Our machines for your application

Machines for the preparation of glass

Shredders

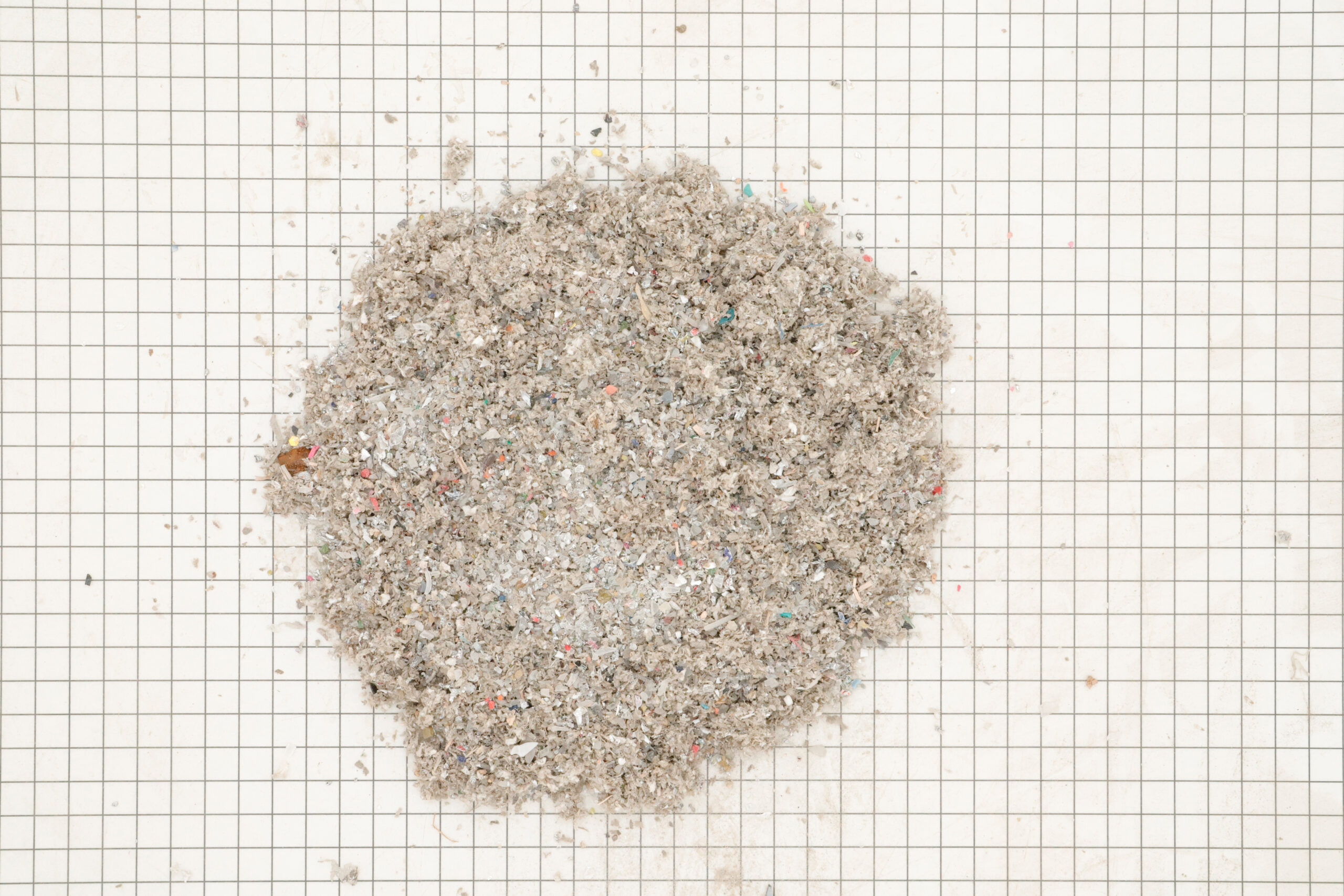

The aim is to tear the film-reinforced panes into small pieces, so that a secondary crusher such as our PTKS impact mill can later separate the film and glass cleanly from each other.

Learn more

Fine grinding mill

Our PTRF fine grinding mill is equipped with one or two rotors, depending on the application. The starting material is mineral products with a feed size of up to 30 mm, depending on the material.

Learn more

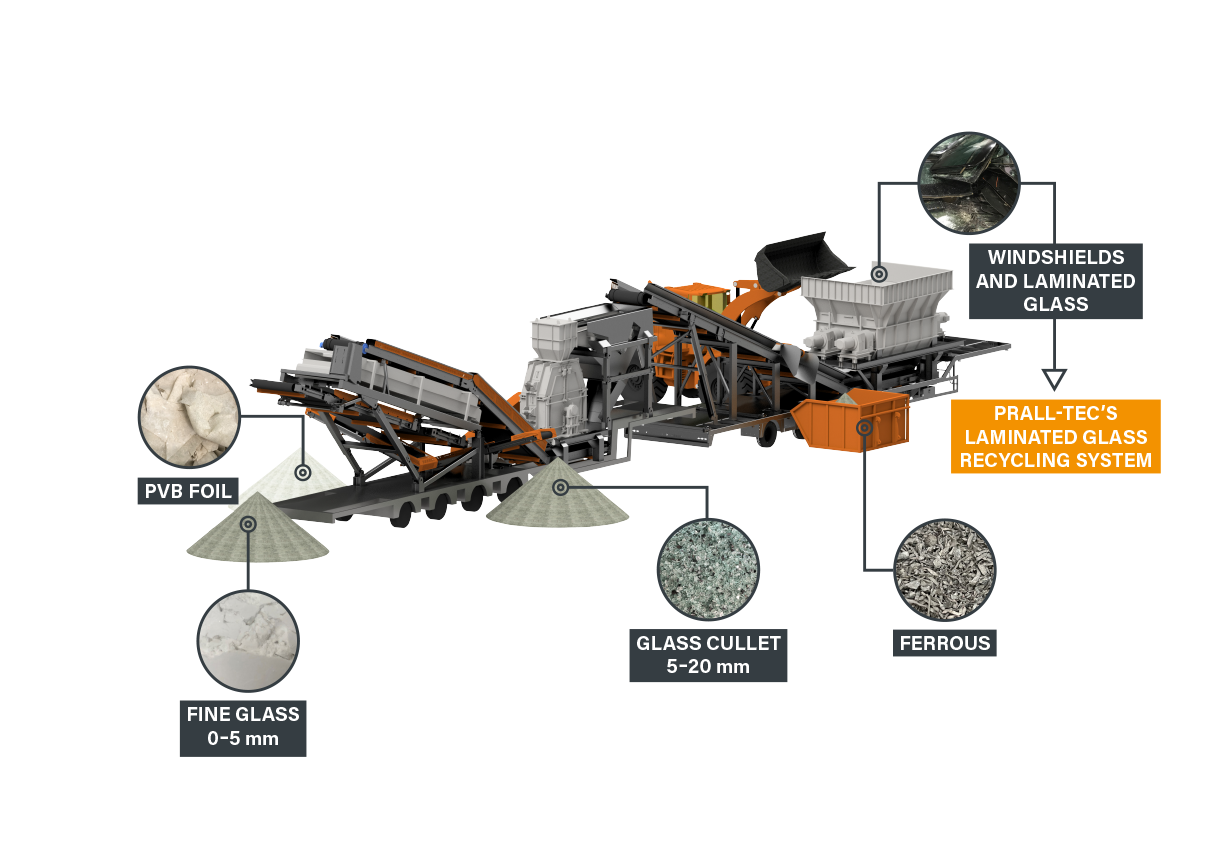

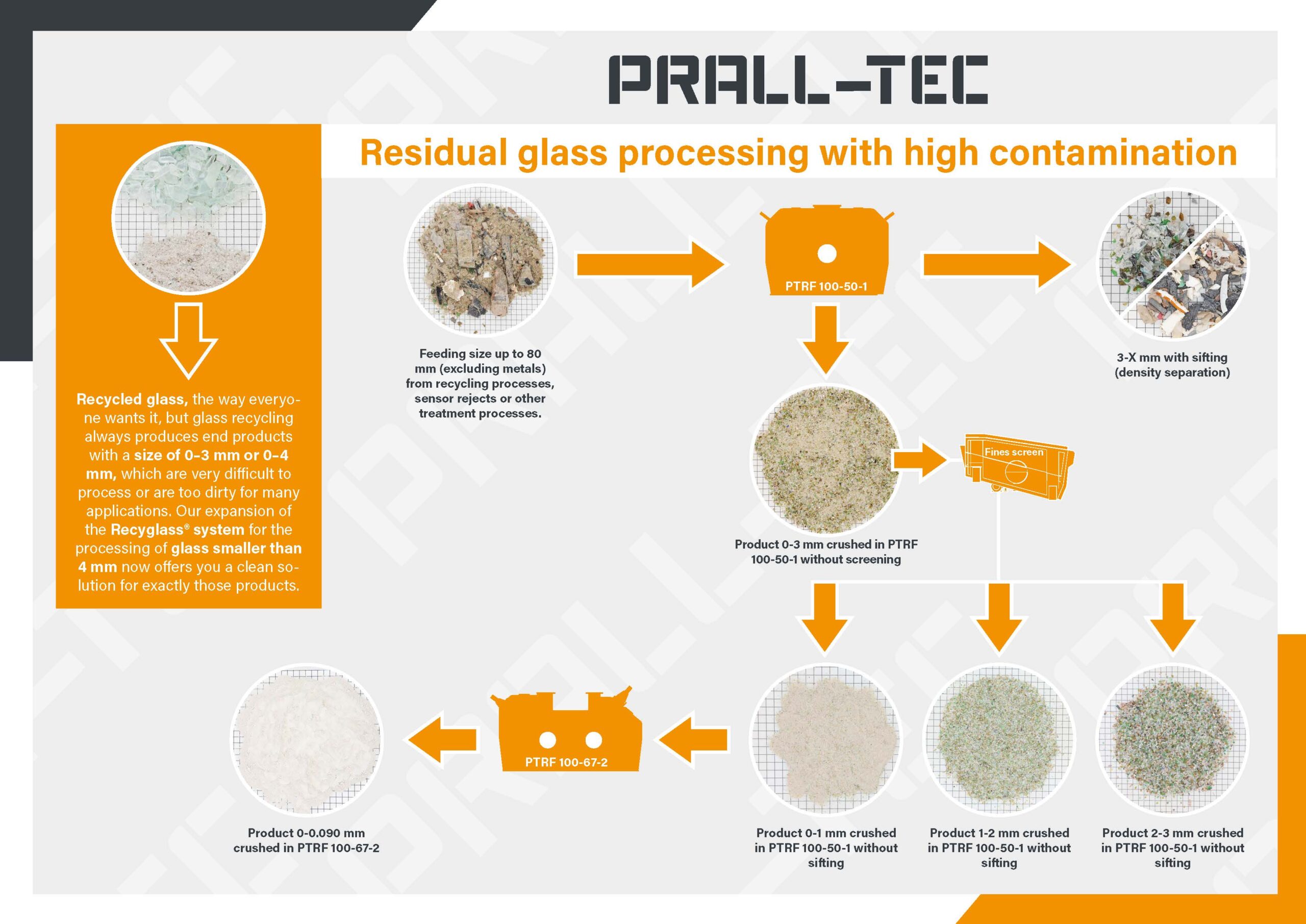

Recyglass®

With Recyglass® you work cost-efficiently in terms of laminated glass reprocessing.

Learn more

Impact crushers

Impact crushers

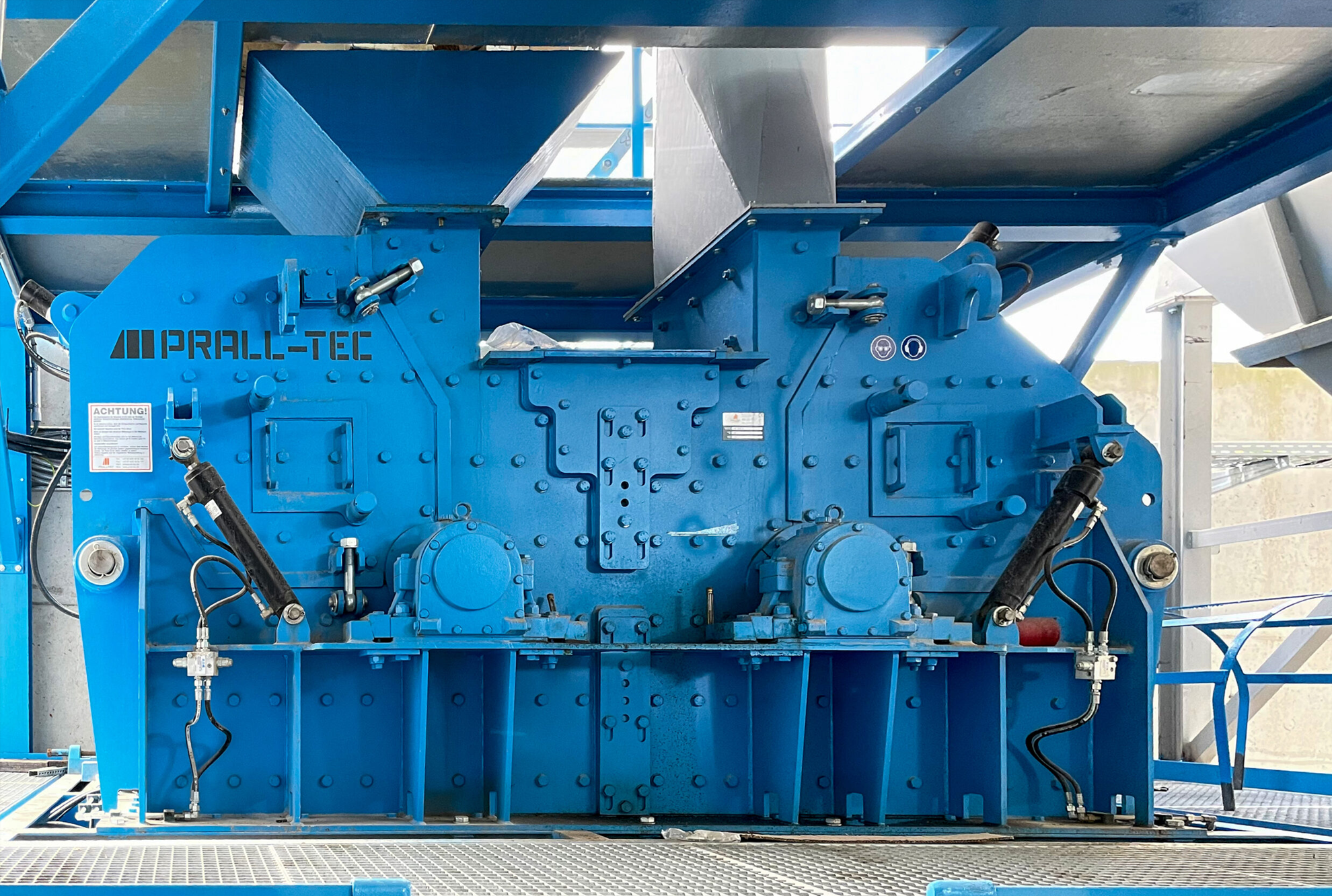

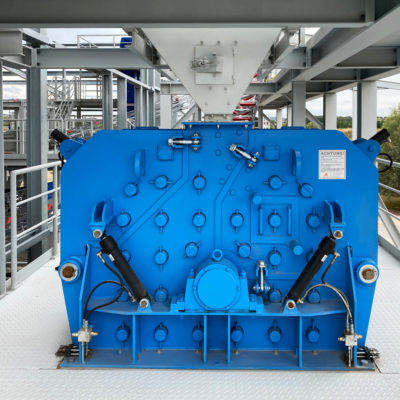

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

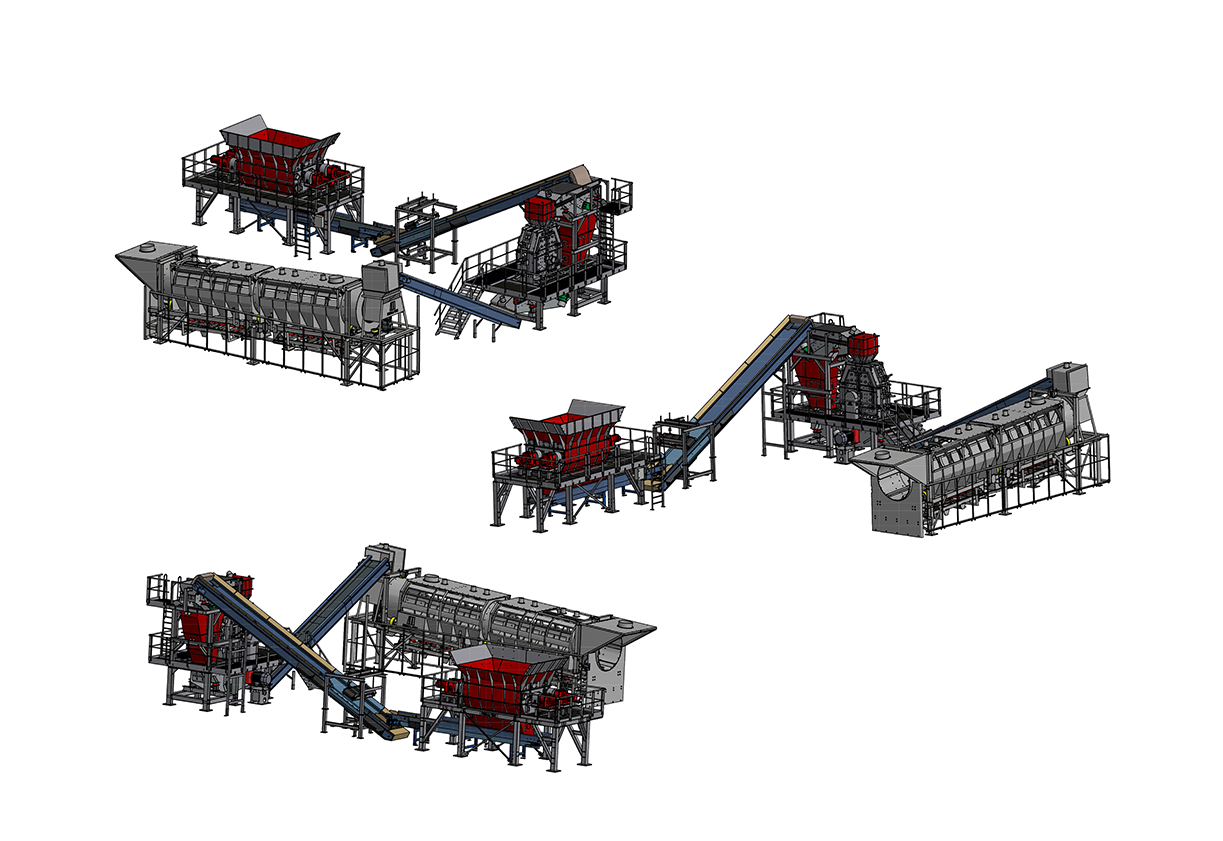

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions