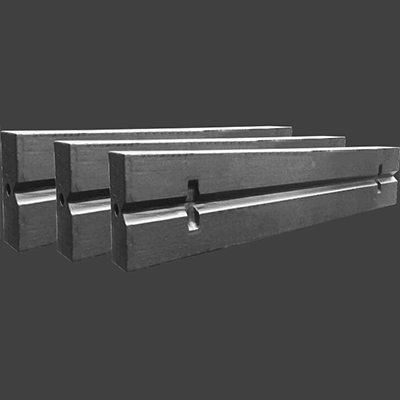

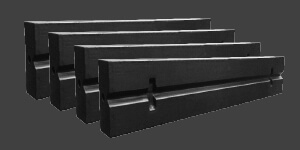

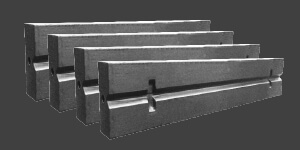

Thanks to the use of ceramics today, impact bars are becoming more and more stable and powerful. Ceramic impact bars are now used in almost every impact mill and are therefore widespread.

We can offer you the right impact bar for every impact mill, because not all ceramics are the same. For the secondary crusher, we can now also fall back on various chrome ceramic blow bars and thus achieve significantly longer service lives with lower maintenance and replacement intervals.

We are happy to advise you and find the right beater bar for your product, if desired also without ceramic in manganese or martensite steel.

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions