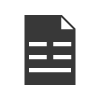

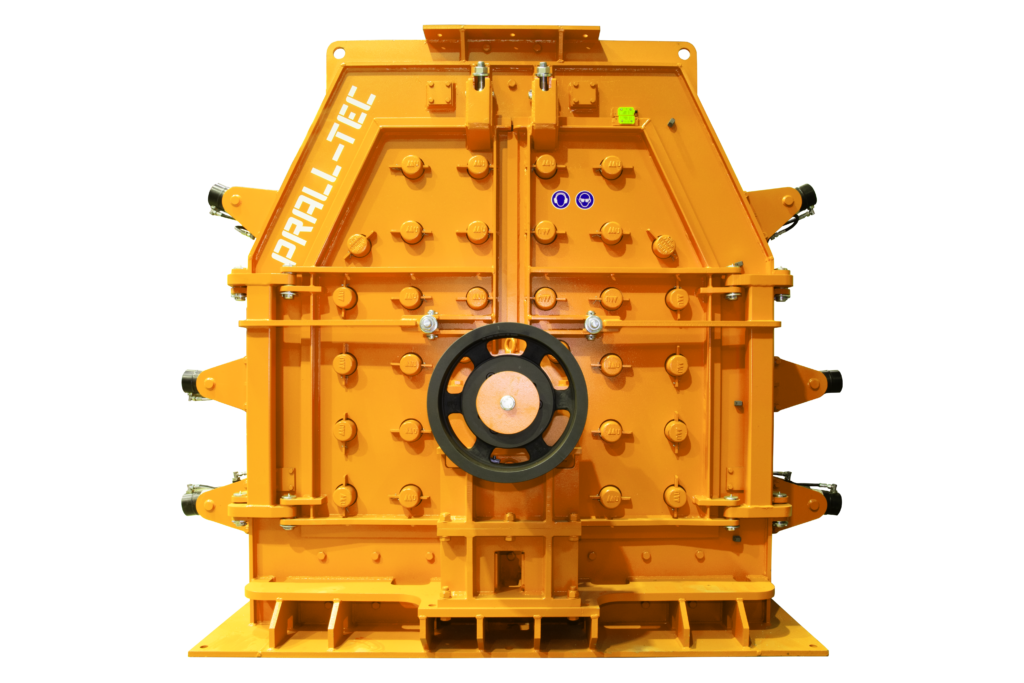

The PTKS Impact Mills are used as reversible secondary crushers and serve for crushing the often unwanted oversized grain with only one crusher directly to a fixed defined size. This is ensured by the front impact of the incoming material and firmly fitted grinding path, so that the crushing can occur at the entire front surface and sharp edge of the impact bar. With the reversible rotor, the flexible setting of the impact crushers and the grinding path, the PTKS Impact Mill offers a number of usage options for diverse materials.

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions