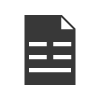

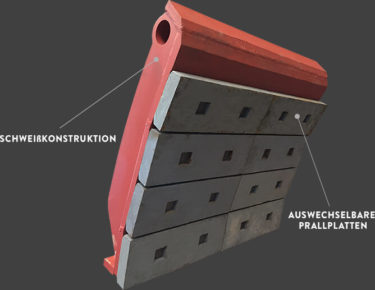

Today, manufacturers frequently rely on the less expensive original equipment and resort to the cast monoblock or multiblock. However, depending on the material and mill, this is significantly more expensive in the long run than an impact unit design with impact plates made of Hardox or cast iron. For this reason, we now replace many monoblocks and exchange them for our impact mills.

Often it is also possible to change the geometry and thus have a positive effect on the material to be crushed. We will be happy to advise you on the possibilities and the cost reduction through the exchange.

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions