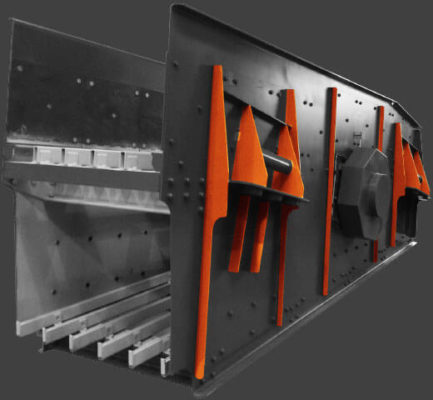

Screening machines / Screening boxes

From the small 3 m long 1-deck screening machine to the 3-deck screening machine for sand and grit to the reinforced pre-screening machine, we can also design your suitable screening machine and manufacture it in-house. We can look back on more than 20 years of experience and rely exclusively on the highest quality products and materials in order to deliver a long-term, productive screening machine according to specification.

Stationary screening stations

In addition to the individual screening machines, we also offer complete screening plants with the necessary steel construction, chutes and conveyor belts. Each screening plant is as different as the various applications. Thus, we realize plants from one source for the most different products like natural stone, building rubble, glass, slag or also scrap. Here, too, the focus is on the customer-oriented solution for the desired application, because your perfect end product is our goal.

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions