Template author

Beiträge von Wedeken:

10 Jun 2025 in

All News

🚂 Today, the narrow-gauge steam locomotive “Hidalgo” from Eisenbahnfreunde Lengerich e.V. was loaded up again and sent back on its way to Itzehoe.

The locomotive had been our guest for the Open Day at the Feldbahn Museum – a true highlight!

The whole operation came about due to the unique challenge of finding a suitable overhead crane for the loading process. When no one else could be found, it was immediately clear to us at PRALL-TEC: We’re happy to help! 💪

We’re proud to support such a dedicated association and say: Safe travels, Hidalgo! 🚂✨

22 Apr 2025 in

All News

We’ve kicked off the installation of a new recycling plant for one of our customers – and this project comes with a special challenge: limited space called for precise planning and a compact design. 💡

At the heart of the setup is our impact mill PT 80/70 G, designed for the efficient processing of clay-based materials like clinker, roof tiles, and bricks. The processed material is fed back into ongoing production – a strong contribution to resource conservation and a sustainable circular economy.

✅ Compact & powerful

✅ High performance in tight spaces

✅ Made in Lengerich – Quality engineered in Germany

👉 Check out the first pictures of the installation right here in the post.

We’ll keep you updated on the progress – stay tuned!

07 Apr 2025 in

All News

We’re at bauma 2025!

Come meet us from April 7–13 in Hall B2, Booth 528 at Magotteaux!

We’ll be showcasing the latest innovations in recycling technology – innovative, efficient & sustainable.

Stop by, ask questions, share ideas – we’re looking forward to seeing you!

12 Mar 2025 in

All News

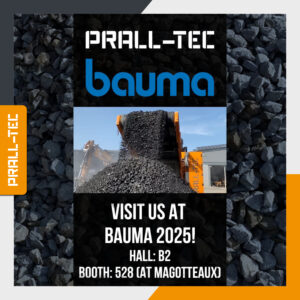

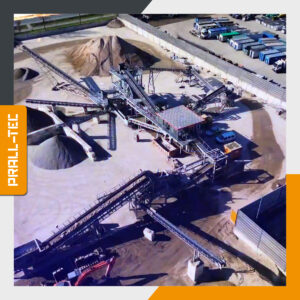

How Is Construction Waste Recycled Sustainably?

Our team visited a modern recycling facility and gained fascinating insights into the process.

At the center of it all: our powerful impact crushers, efficiently crushing and preparing the material for reuse.

See for yourself how innovative construction waste recycling works!

📽️ Watch the video

30 Jan 2025 in

All News

Our assembly team is in action this week! We’re bringing the jaw crusher we repaired back to life. 🦾🔥

Since the machine parts aren’t exactly lightweight, we called in a strong helper – the crane! 🏗️

This job requires precision, strength, and top-notch teamwork! 👷♂️⚙️

Soon, the machine will be running smoothly again. 😎👌

23 Jan 2025 in

All News

Other impact crushers? They would have clocked out for the day just at the sight of this massive piece of iron (770 x 300 x 60 mm). 😅 But our PT130-130 impact crusher? It just let out a tired yawn. 🦾💤 A customer sent us this photo: While recycling debris from a bridge demolition, this iron piece ended up in the impact crusher. And what happened? Nothing. 🙌 Our machine isn’t built out of cardboard. 😉 The iron, on the other hand, took quite a beating – the winner by knockout in Round 1: our impact crusher. 🏆💥

22 Jan 2025 in

All News

Our welders deliver excellence every single day: creating products that are stronger and more resilient than ever before. 💪🔩

✅ 100% Quality

✅ 100% Passion

✅ 100% Made in Germany

True strength is built with precision, passion, and quality – straight from Lengerich.

20 Jan 2025 in

All News

While we can’t repair everything, don’t worry – in case of severe damage from foreign objects, we can offer you a cost-effective replacement rotor. 💡

We tailor it to your specific needs, such as special hardfacing, a front support bar instead of holding pieces, or any other custom adjustments. 🔩

Learn more

17 Jan 2025 in

All News

Our Balling Mills provide the perfect solution for efficient and sustainable recycling. Equipped with the latest technology and a robust design, they are ideal for even the most demanding recycling applications.

Thanks to their exceptional performance and durability, they can continuously process large volumes of materials, making them a valuable investment for companies looking to optimize their recycling processes. Our ball mills offer a reliable and cost-effective solution for recovering valuable metals.

Choose quality, performance, and sustainability with our ball mills for your recycling needs!

Order your machine now!

15 Jan 2025 in

All News

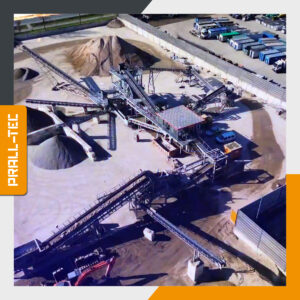

Soon, it will be on its way to our customer. 💪

This machine was manufactured with the utmost precision and care here in Lengerich – Made in Germany! 🇩🇪

Durable, robust, and efficient – our team has once again delivered outstanding work. 👏 The PTRF 130-67 is used for fine grinding of mineral material in household waste as a pre-crusher. Combined with our PTV balling mill, it ensures optimal processing of the valuable metals contained in the waste. 🌍♻️

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions